mSense’s VisionDLTM for automatic frame number verification

One of the leaders in high volume Asian motorcycle manufacturing is always looking for new ways to improve their manufacturing production efficiency. This use case describes how the mSense metal stamp character reader improved their frame number verification with an automatic ergonomic solution.

The current frame number verification process is very tedious

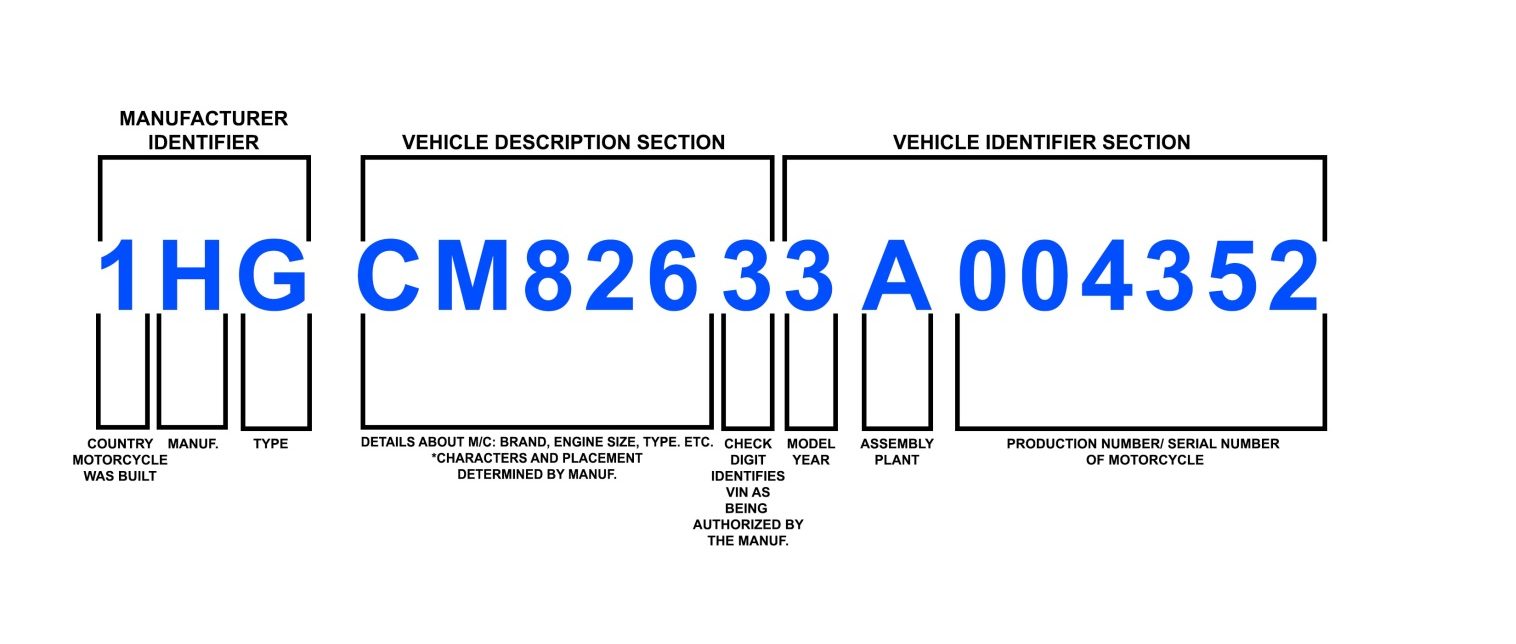

One critical task in vehicle quality inspection is the verification of the metal-stamped frame number with the assembly document number to trace the inspection results. The current method requires an assembly line operator to read the metal-stamped frame number using a flash light and verify if it matches the assembly document. Needless to say this process is a tedious and error prone task because:

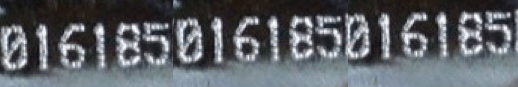

- The location and reflection off the metal make reading the frame number difficult as shown in Figure 1.

- During the reading, the engine is on a moving conveyor.

mSense’s robust and ergonomic solution

For the assembly line operator’s productivity and enhanced safety, the manufacturer tried several vendors to see if an automated frame number verification solution was possible. mSense’s automatic, ergonomic and robust solution exceeded the customer’s expectations..

Figure 1. Typical frame number image with 17 characters

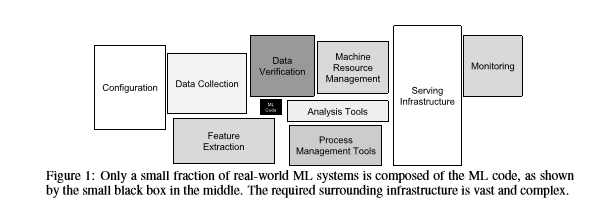

mSense’s VisionDL™ system based metal stamp reader is in production with:

- Reduced errors: Achieving traceable 99% plus accuracy well beyond the previous manual technique,

- Improved assembly line technician’s productivity and job satisfaction: the new process is automatic and the assembly line operator typically in 8 seconds scans the engine frame number, processes the image, and verifies that the frame number matches the documentation. This is all done automatically with operator audio and visual indicators.

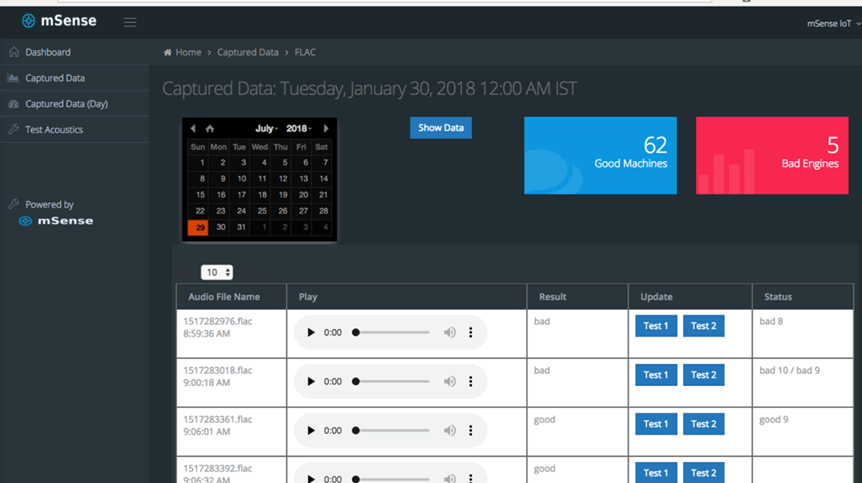

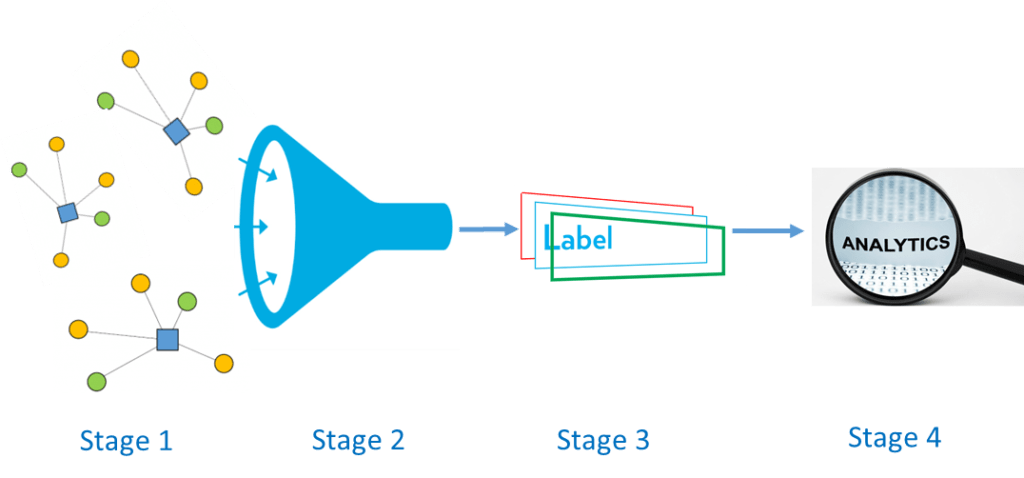

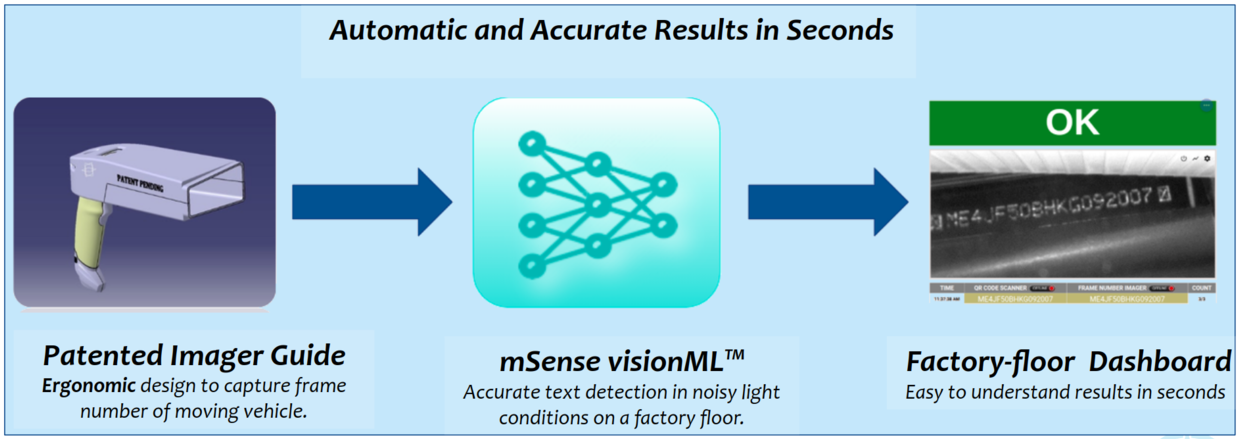

As shown in Figure 2, mSense’s automatic frame number verification solution is comprised of three modules.

- Patented handheld imager guide: The assembly line technician simply positions the scanner over the serial number (even while the engine is moving) and scans an image. This image is then sent to the industrial PC. Depending on customer requirements, fixed camera installation is also available.

- mSense VisionDLTM model processes the image and accurately recognizes the text even in low light conditions. This VisionDL model is executed on the industrial PC.

- Factory Floor dashboard- Finally the same industrial PC displays the results with the proper indicator of “GO” for a match and “NG” for a mismatch. This dashboard includes other information for redundancy and to insure easy detection of the mismatch. From the time the scanner captures an image to the final results is typically less than 3 seconds. Audio/visual indicators are provided on the handheld imager as well.

Figure 2. mSense’s automatic frame number verification system for the factory floor showing the three major solution modules.

A faster, better and safer assembly line process:

mSense’s solution enabled the manufacturer to increase the operator’s productivity and their assembly line efficiency: a faster, better and safer assembly line process with the following benefits:

- 6X improvement in frame number verification productivity

- 100% traceable accuracy, and

- cost effective.

For more information on metal stamp character reader, contact Info@msense.ai