With advancements in new technologies, like Internet of Things (IOT), Cloud Computing and Machine Learning(ML), the modern manufacturing process has come a long way during the last few years. A new paradigm has emerged, creating Industrial 4.0 revolution, where the combination of sensors, edge data processing and ML algorithms allow manufacturing plants to not only to digitize, automate, and optimize the work flow, but also to provide early detection of any mechanical issues.

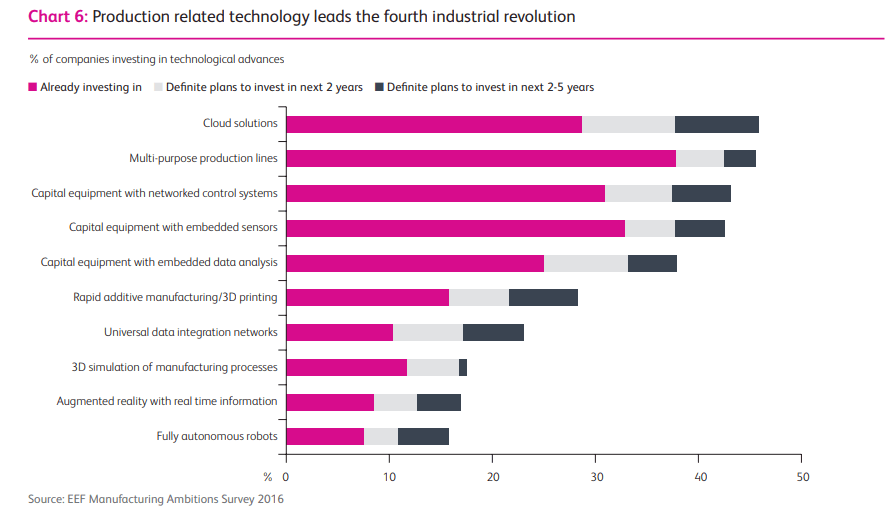

Companies, as shown in Figure 1[i], are trying to move up the value chain, by exploiting the top 5 digital technologies – Cloud Computing, Network Control Systems, and Equipment with Embedded Sensor and Control Systems, and AI. However, they struggle with how to best utilize their existing data, pull together new sensor data and combine it with software tools, and talent to deliver on this transformative business potential.

Figure1: Production related technology leads the fourth industrial revolution1

AI is not a very good organizational fit:

A recent PWC report [ii] highlighted that AI requires new organizational thinking. Customarily Chief Information Officers are leading most digital transformation efforts. However, as mentioned above, AI is a convergence of data, sensor physics, distributed networks/ IoT, and ML, which spans the manufacturing enterprise from business units to manufacturing operations, to data specialist, to IT.

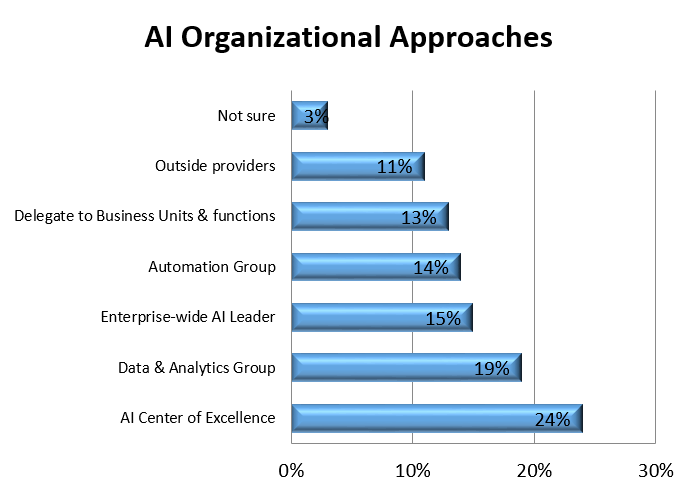

As testimony to this new organizational thinking, Figure 2 shows the varied approaches taken from 1,000 executives’ 2019 AI plans with most predominant option being creating an internal center of excellence, which might not be the right approach, considering scarcity of talent and expertise in this area.

Figure 2: The many 2019 AI organizational approaches

You do not want a research experiment

Is an AI approach the right one to solve your problem? Most enterprises do not want to take the time and money to run a research experiment to answer this question. Instead what is needed early on is a technique to know what results AI can achieve and are all the pieces, such as sufficient data available.

To complicate this question often AI offers a trade-off in the amount of labeled data and the result’s accuracy such as a classification confidence percentage. Understanding if an acceptable confidence score of 60% or 70% may provide sufficient accuracy is paramount to harvesting early AI potential benefits.

The enterprise AI workflow

Getting the right people at the right time to work together will realize the full potential of AI. Leveraging an enterprise’s areas of expertise is required to integrate data, ML algorithms,and IT infrastructure into an end to end solution from manufacturing data such as sensors to the appropriate ML algorithm to realizing a tangible business ROI.

What is needed is a software AI enterprise workflow that allows for iterative collaboration and appreciation for each step in the AI journey. A practical enterprise workflow will automatically handle most of the tedious steps in the process while exposing critical steps such as feature engineering for review and implementation.

Being able to capture manufacturing expertise such as factory floor inspections and converting that into labeled data for ML training to improve assembly run rates is just one example of how an integrated end to end AI workflow can realize the full potential of AI to transform businesses.

As described in subsequent posts, mSense offers a customer proven practical AI enterprise workflow solution that accommodates the enterprise’s current organization and talent.

[i]https://www.eef.org.uk/~/media/c98ecc3376c44cbd86b2093cd086ca8e.pdf?la=en

[ii] https://www.pwc.com/us/en/services/consulting/library/artificial-intelligence-predictions-2019

One Reply to “Artificial Intelligence- Driving the New Industrial Revolution (Industry 4.0)”

Comments are closed.